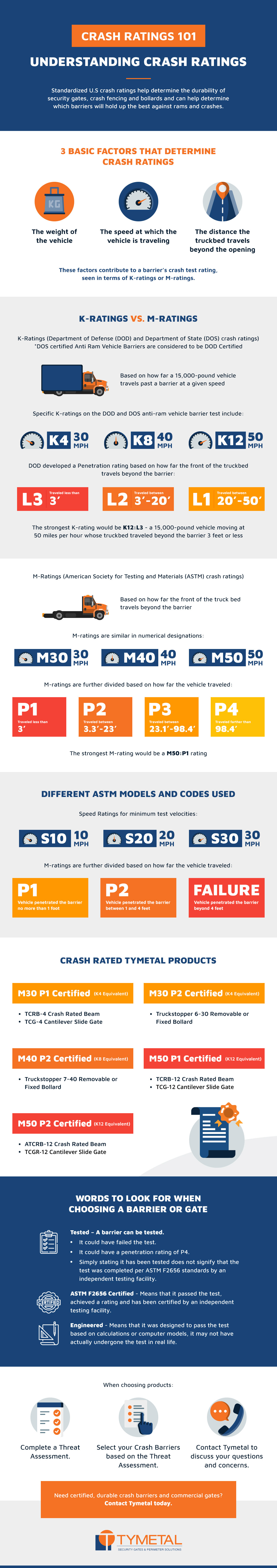

Understanding Crash Ratings

Bollards and security gates play a crucial role in protecting entrances from unauthorized access and minimizing damage during accidental collisions. These security measures are essential for modern industrial and defense applications. To ensure the effectiveness of these barriers, standardized and unbiased U.S. crash ratings are used to evaluate their durability. Understanding crash ratings can help you choose the most suitable barriers that can withstand impacts from vehicles. If you're looking for secure gates or bollards, paying attention to crash ratings is key. This guide will explain how to interpret crash ratings for gates and bollards effectively. Three main factors determine the crash test ratings: Some rating systems only award certification if the vehicle doesn’t go beyond a certain distance — anything beyond that isn’t certified. Together, these three factors define a barrier’s crash rating. You may encounter ratings labeled as K-ratings or M-ratings, so it's important to understand the differences between them. K-ratings, developed by the Department of Defense (DOD) since 1985, are based on how far a 15,000-pound vehicle travels past a barrier at a specific speed. For a barrier to be certified under K-ratings, the vehicle must travel no more than 50 feet beyond the barrier. Higher K-ratings indicate tests conducted at higher speeds with the same vehicle type and weight. Common K-ratings include: K-ratings are further divided into L1, L2, and L3 classifications based on how far the front of the vehicle traveled beyond the barrier: The strongest K-rated barrier would be K12: L3, where a 15,000-pound vehicle moving at 50 mph penetrates less than 3 feet. When interpreting K-ratings, use the "K" number to determine the test speed and the "L" number to assess how far the vehicle traveled beyond the barrier. M-ratings have replaced K-ratings in recent years, following standards set by the American Society for Testing and Materials (ASTM). Unlike K-ratings, which measure how far the front of the vehicle goes beyond the barrier, M-ratings focus on how far the vehicle's payload travels beyond it. They also consider vehicle size, speed, and distance traveled. M-ratings are similar to K-ratings in that their numerical designations correspond to test speeds. For example, a K4 rating is equivalent to an M30 rating, a K8 matches an M40, and a K12 corresponds to an M50. The vehicles in these tests traveled at 30, 40, and 50 mph, respectively. M-ratings and K-ratings are often considered interchangeable. M-ratings are also classified into P1, P2, P3, and P4 based on the distance the vehicle traveled beyond the barrier: M-ratings allow for longer distances than K-ratings, making them more accurate. An M50: P1 rating is equivalent to a K12: L3 rating. Meanwhile, an M50: P2 rated beam can withstand a 15,000-pound vehicle moving at 50 mph without allowing it to travel more than 23 feet. It's important to distinguish between “tested,†“certified,†and “engineered†when evaluating crash-rated products. Each term has different levels of significance: When choosing a barrier, always aim for “certified†M-ratings or K-ratings. If you see labels like “tested†or “engineered,†ask whether they actually met the standards and whether they were physically tested. Without real testing, there's no guarantee the product will perform as expected in real-life scenarios. As mentioned earlier, ASTM uses various models and codes to classify anti-ram tests based on vehicle speed, weight, and distance traveled. Understanding these codes is essential for interpreting crash ratings. Learn more about ASTM standards for vehicle security barrier crash tests. Key speed ratings include: Penetration ratings for low-speed tests include: For high-speed tests, the standards are slightly more flexible: When security is a top priority, you need barriers that meet high standards. At TYMETAL, all our security gates and crash barriers have achieved prestigious ASTM crash ratings. You can rest assured knowing our barriers meet universal, unbiased standards. Shop durable crash barriers and commercial gates from TYMETAL today. Reviewed By Chris Herold on 4/29/2021 Anti-slip / Anti-pilling Agents Suitable

for improving the anti-slip and anti-split properties of various recycled and

synthetic fibers.

It can significantly

improve the anti-slip performance of yarn and improve the anti-pilling

performance of yarn and fabric.

The film is cross-linked to

form a mesh structure on the surface of the fabric, which significantly

improves the anti-slip properties of various slip-prone yarns.

anti-slip, easy-to-slip textiles, anti-splitting, anti-pilling, cross-linked Dymatic Chemicals, Inc. , https://www.dymachem.comGuide to Understanding Crash Ratings

The 3 Factors That Determine Crash Ratings

K-Ratings: Older Standards

M-Ratings: Modern Standards

Tested vs. Certified vs. Engineered

Different ASTM Models and Codes Used

Buy Certified Security Gates and Perimeters From TYMETAL